Food Manufacturing

Slips, Trips and Falls in the Food Manufacturing Industry – can you demonstrate you are not liable if an incident occurs?

As anyone working at a food manufacturing site will know, the level of contamination, debris and liquid that reaches the floor is usually much higher than some other premises you might work in. This is due to the nature of the work undertaken there and the various stages of the processes that take place.

This in turn means that we frequently see wet and unsafe floor surfaces and increased slip risk within food manufacturing sites. As a result, instances of slips, trips and falls, the number one cause of workplace injury, are higher too.

Therefore, it is vital to demonstrate your duty of care and fulfil your obligations to reduce and manage your slip risk. This ensures the safety of those travelling across your floor surfaces so far as is reasonably practicable as required by the Health & Safety at Work Act.

There are so many changes to the environment within a food manufacturing site, and each area is different with constant activity. As a result, some of the frequent problems we see on sites are:

- Build-up of debris forming layers on the floor surface.

- Various types of contamination to consider – e.g. crumbs, powders, dust etc.

- Spillages from product and machinery – e.g. steam, water, liquid or poor drainage resulting in pooling on the floor.

- Greases reaching the floor surfaces.

- Cleaning regimes often focussed soley on hygiene with little consideration for slip resistance.

- Frequent changes in floor type that all behave differently – e.g. loading bay vs wash/hygiene areas.

- High frequency foot traffic.

- Obstacles and clutter in walkways.

- Floor degradation.

- Footwear changes to consider.

Each site is different, with its own unique considerations. The key to managing slip risk effectively is to take a tailored approach. For example, the cleaning regime in an area where grease reaches the floor would be very different to an area where crumbs reach the floor.

Take a look at this video regarding cleaning up fat content and how we often see people spread the slip risk as opposed to clean it up.

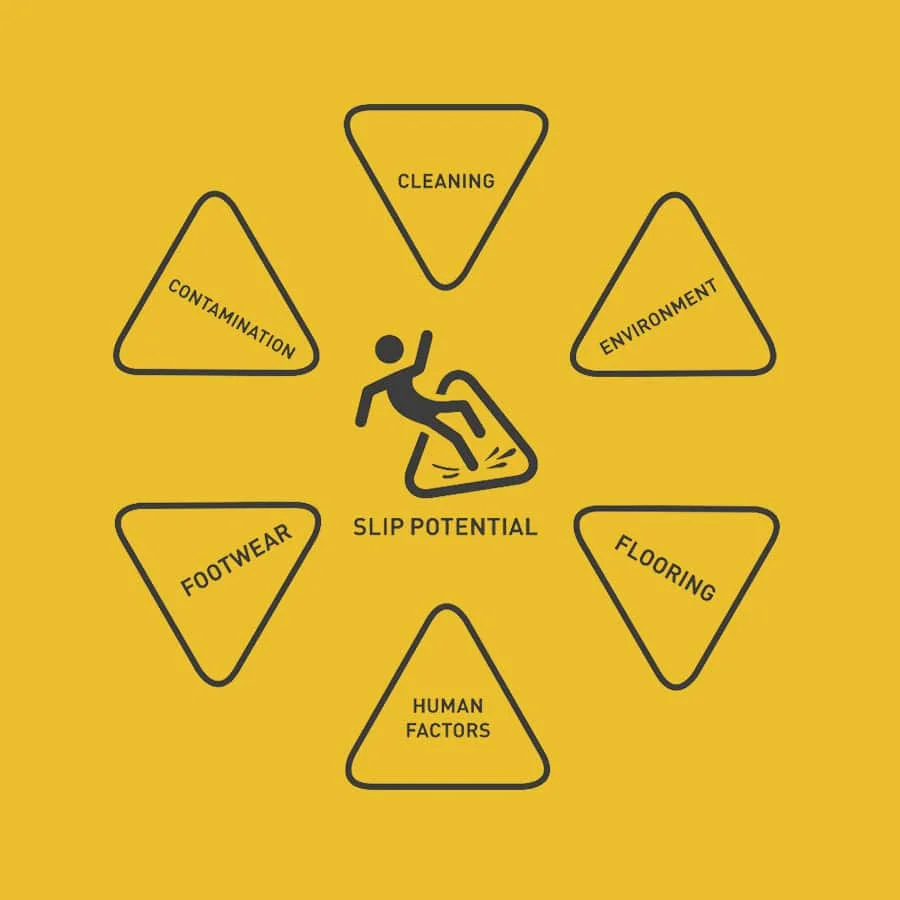

It is also really important to remember there are 6 factors that impact slip risk and most of these are always going to be applicable in food manufacturing sites. All too often we see managers focus on one key area only, or not consider all the elements of slip risk or indeed how they are linked.

The key areas to be addressed when managing slip risk at food manufacturing sites are:

- Methods to control and reduce contamination.

- Correct cleaning regimes, which vary in different areas.

- Effective waste removal.

- Controls in place to break down contamination and implement preventive measures.

- Staff awareness, training, and accountability.

- Recommendations and procedures to improve current measures, with continuous improvement.

- Understanding the slip resistance of your flooring in-situ as your starting point.

- Considering the impact changes in your products and processes may have on slip risk.

- Any protective clothing and footwear staff may need to wear in certain areas.

Did you know?

So far this year slips have cost society at least:

50%

of all accidents to the public are slips and trips.